PP Hollow Building Formwork Extrusion Line

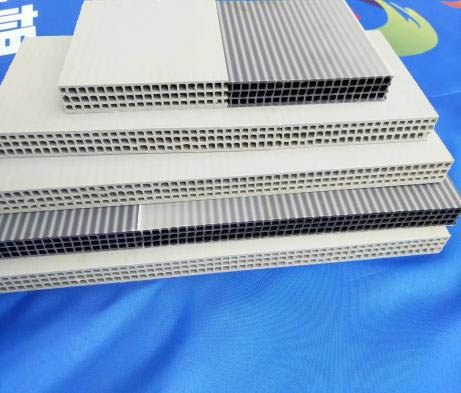

Ụdị ụlọ PP ogherebụ ngwaahịa nchekwa gburugburu ebe obibi na-echekwa ume na akwụkwọ ndụ akwụkwọ ndụ. Ọ bụ ọzọ ọgbọ ọhụrụ ngwaahịa mgbe osisi formwork, jikọtara ígwè formwork, achara osisi glued formwork na niile ígwè nnukwu formwork. Ọ nwere ike dochie kpamkpam nchara nchara na usoro osisi, na nchekwa ike, nchekwa gburugburu ebe obibi na ọnụ ala amortization dị ala.

Uru asatọ

1. Dị nro ma dị nro. A ga-egweri ihe arụrụ arụ ahụ nke ọma na nke ọma. Mgbe demoulding, elu na imecha nke ihe Ọdịdị ga-akarị teknuzu chọrọ nke dị mma chere ihu formwork. Ọ dịghị mkpa maka plasta nke abụọ, nke na-azọpụta ọrụ na ihe.

2. Ìhè na mfe iyi. Na ìhè arọ na ike usoro adaptability, ọ nwere ike sawed, planed, gbapuru na ntu, na ike na-etolite ọ bụla geometry na uche izute mkpa nke ụlọ formwork nke dị iche iche shapes.

3. Mfe demoulding. Kọnkịta ahụ anaghị arapara n'elu slab ahụ ma ọ dịghị mkpa ihe ntọhapụ. Ọ dị mfe ịkwatu ma wepụ ntụ.

4. Stable na ihu igwe na-eguzogide. Ike igwe dị elu, enweghị ọzịza, mgbawa, nrụrụ, nha kwụsiri ike, nguzogide alkali, mgbochi corrosion, ire ọkụ na mgbochi mmiri, oke na ihe na-egbochi ụmụ ahụhụ n'okpuru okpomọkụ nke - 20 ℃ ruo + 60 ℃.

5. Na-akwado mmezi. The formwork adịghị etinye mmiri na ọ dịghị mkpa pụrụ iche mmezi ma ọ bụ nchekwa.

6. Ike mgbanwe. Enwere ike ịhazi ụdị, ọdịdị na nkọwapụta dịka ihe achọrọ nke injinịa ihe owuwu si dị.

7. Belata ego. Oge ntụgharị dị ọtụtụ, ụdị ọrụ ụgbọ elu adịghị ala karịa ugboro 30, na kọlụm beam formwork abụghị ihe na-erughị ugboro 40, yana ọnụ ala dị ala.

8. Nchekwa ike na nchekwa gburugburu ebe obibi. Enwere ike ịmegharị ihe niile fọdụrụ na ihe mkpofu.

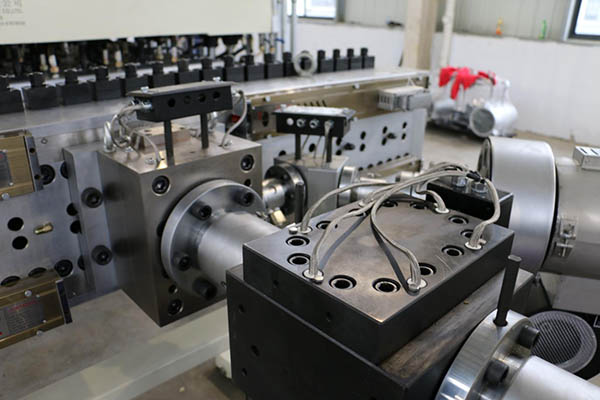

JWELL mepụtara PP otu ebu okpukpu abụọ na-emepụta ahịrị nrụpụta ụlọ na ndabere nke ahịrị mmepụta 915mm ọdịnala, nke na-abụghị naanị nwere ike gboo mkpa nke nnukwu mmepụta na ike dị ala.

Njirimara

1. Atọ oyi akwa coextrusion mmepụta akara

2. Ihe nkesa ihe mejupụtara oyi akwa atọ

3. Multi-layer lattice ebu

4. bọọdụ ụdị ọkwa atọ

5. traktọ jikọtara ọnụ

6. Igwe eji egbutu ogologo oge akpaaka

Nkọwapụta teknụzụ isi

|

Nlereanya |

Ihe onwunwe |

Nkọwapụta extruder |

Ogologo ngwaahịa (mm) |

ọkpụrụkpụ (mm) |

Ike(kg/h) |

|

JWS130 (80)-1320 |

PP gbanwetụrụ ihe |

JWS130/35, JWS80/35 |

915/1220 |

12-14/15-17 |

450-500 |

|

JWS150 (80) -2000 |

PP gbanwetụrụ ihe |

JWS150/35, JWS80/35 |

915*2 |

12-14/15-17 |

550-600 |

|

CJWH85 (80/52) -2000 |

PP gbanwetụrụ ihe |

CJWH85, CJWH52/JWS80 |

915*2 |

12-14/15-17 |

600-700 |

Mara: Nkọwapụta ndị a nwere ike ịgbanwe na-enweghị ọkwa mbụ.

Ngosipụta onyonyo ngwaahịa

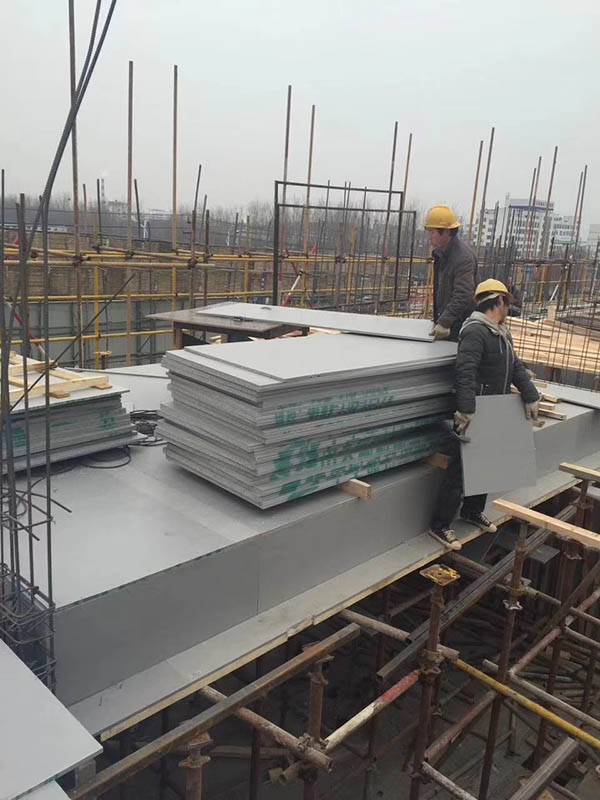

Ebe owuwu ihe